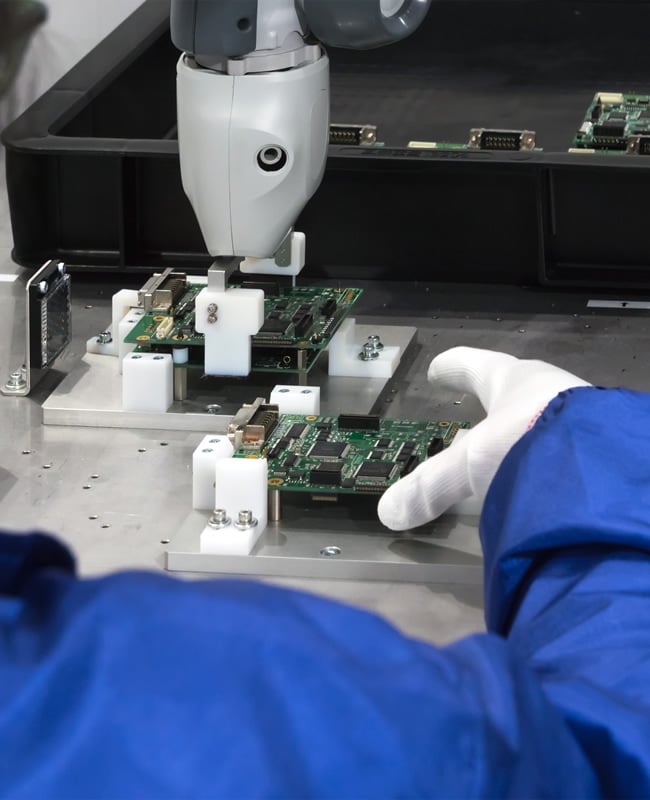

Cobots (collaborative robots) and traditional robots are pivotal components of modern manufacturing, offering automation solutions that significantly impact production processes.

Cobots, in particular, are designed to collaborate with human workers, bridging the gap between automation and human interaction. These robots can be employed in tasks that require precision, repetitiveness, or safety concerns, such as assembly line operations, material handling, and quality control. Traditional robots, on the other hand, excel in highly repetitive, heavy-duty tasks like welding, painting, and packaging. By taking on these roles, cobots and robots enhance manufacturing efficiency, reduce the risk of errors, and boost productivity. In today’s manufacturing landscape, they are indispensable tools for optimizing operations and maintaining a competitive edge.

Robot and Cobot applications we offer:

- Material Handling

- Palletising

- Machine Tending

- Quality Inspection

- Part Assembly

- Material removal

Manufacturers we work with

MANUFACTURINGRobots for industrial automation

Industrial robots offer a multitude of benefits in manufacturing and industry, including enhanced efficiency, consistent quality, and increased productivity. They excel in tasks that are repetitive, hazardous, or require precision, reducing the risk of errors and workplace accidents. Robots also contribute to cost savings through reduced labor requirements and faster production cycles. Moreover, they can operate 24/7, allowing for continuous production, and their flexibility to adapt to various tasks and applications makes them invaluable tools for staying competitive in today’s rapidly evolving industrial landscape.

Examples of industries our robots can be used:

- Food industry - Fast moving consumer goods (FMCG)

- Pharmaceuticals - Picking warehouses

- Metalworks - CNC workshops and metal forming factories

Food Robots and Cobots for sterile environments

Robots in food factories streamline production, ensuring consistency, precision, and hygiene while meeting high demand in the food industry.

Robots play a pivotal role in revolutionizing food manufacturing by offering a range of benefits. In food factories, where strict quality and hygiene standards are paramount, robots ensure consistency and precision in tasks such as sorting, packaging, and quality control. They significantly reduce the risk of contamination and improve food safety. Moreover, these automation solutions enhance operational efficiency, allowing food factories to meet the high demand for various products while keeping production costs in check. By taking on repetitive, labor-intensive tasks, robots free up human workers to focus on more complex and creative aspects of food production, ultimately contributing to increased output and product quality in the ever-evolving and competitive food industry.

We have their backTrusted by