Programmable Logic Controllers (PLCs): The brains behind industrial automation.

PLCs are the central nervous system of industrial automation, governing and coordinating complex machinery and processes. At our business, we pride ourselves on our expertise in PLCs, having honed our skills over years of working with diverse industries. We excel in designing, programming, and maintaining PLC systems that drive efficiency and precision in manufacturing, offering tailored solutions that meet the unique demands of our clients. Our commitment to staying at the forefront of PLC technology ensures that we deliver innovative and reliable automation solutions, making us your trusted partner for optimising your industrial operations.

Common makes of PLC’s our software engineers use but are not limited too:

- Siemens

- Mitsubishi

- Rockwell Allen Bradley

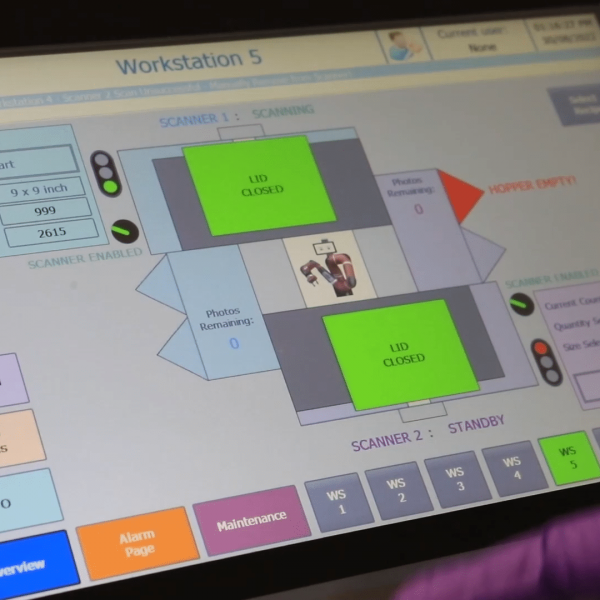

HMI SystemsHuman Machine Interface (HMI)

We’re skilled HMI programmers, and we’re here to help your business. Our team specialises in creating user-friendly and effective Human-Machine Interfaces (HMIs). We design interfaces that make it easy for operators to control and monitor machinery, improving efficiency and reducing errors. With our experience and expertise, we offer practical solutions to boost your productivity and success.

Example software we use:

- Siemens WinCC

- Mitsubishi GOT

- FactoryTalk View

SCADA SystemsSupervisory Control and Data Acquisition (SCADA)

SCADA systems provide real-time control and monitoring of industrial processes, ensuring efficiency and reliability.

Looking to boost your industrial efficiency? SCADA systems are one of the most proven ways to do so. We’re experts at setting up SCADA solutions that provide real-time control and monitoring for your processes. With our practical approach, you can expect smoother operations, less downtime, and better decision-making. Get in touch and we will help you get the most out of your industrial processes with our SCADA solutions.

- Wonderware Intouch

- Ignition by Inductive Automation

- EcoStruxure Machine SCADA Expert

- GE Digital's iFIX

- Winlog by Sielco Sistemi

Siemens PLC software engineering & integrators

We are skilled Siemens PLC software engineers and integrators. With a strong grasp of Siemens technology, we create custom PLC solutions that fit your needs. Our practical approach ensures reliable control systems, increased productivity, and less downtime. We have a proven track record of implementing Siemens PLC solutions effectively, making us the go-to choice for automation that works for your business.