A proof of concept serves as a practical demonstration to validate the feasibility and potential of an idea or innovation

Our proof of concepts incorporate a dynamic approach that integrates 3D modelling, simulation, and prototyping. We begin by creating detailed 3D models of the concept, allowing us to visualise and analyse its design and functionality. These models serve as the foundation for simulation, enabling us to assess its performance in a virtual environment, identify potential issues, and refine the concept. Finally, we bring the concept to life through prototyping, constructing physical models or prototypes to validate its real-world functionality and ensure it meets the desired objectives.

This comprehensive approach ensures that our proof of concepts are not only well-conceived but also thoroughly tested and refined before implementation, minimising risks and maximising success.

How our proof of concept simulation service can help:

- Reduces Risk

- Proves Feasibility

- Lower Cost

Proof of Concept Simulation Services

Our POC collaboration with you

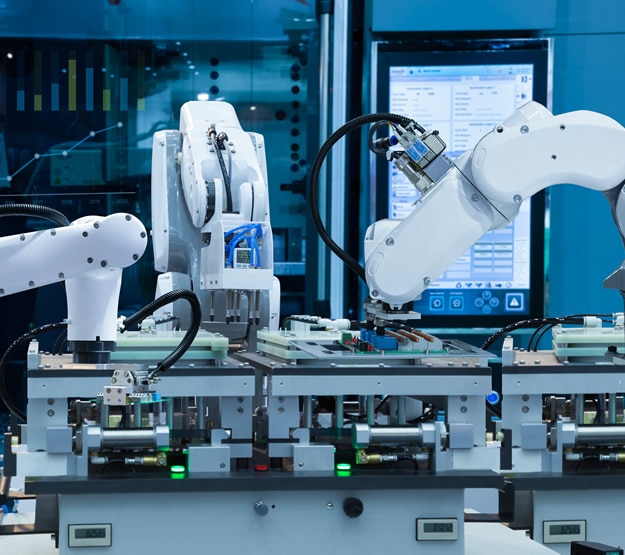

Throughout the whole process we will be working for you. Typical POC include…

- Feasibility studies

- Visualisation

- Simulations

- Real World Testing

- Designing

- Establishing ROI (Return On Investment)

- Prototyping

- Research

- Information Sharing

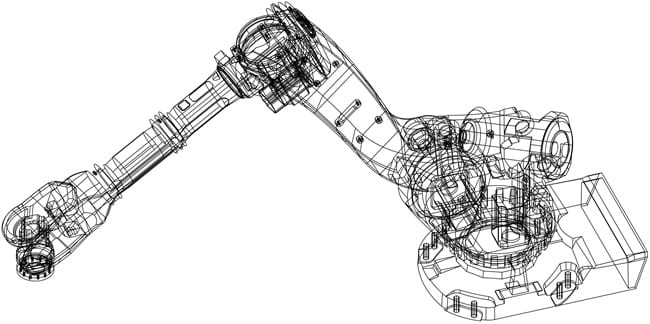

3D Cad designs and modelling Software

At CBM-Logix, our team are highly trained and skilled at CAD modelling for machinery and robotics.

Modelling involves creating detailed 3D designs that enable precise visualisation and simulation of mechanical and robotic systems, aiding in their development and optimisation. It plays a critical role in design, prototyping, and production processes.

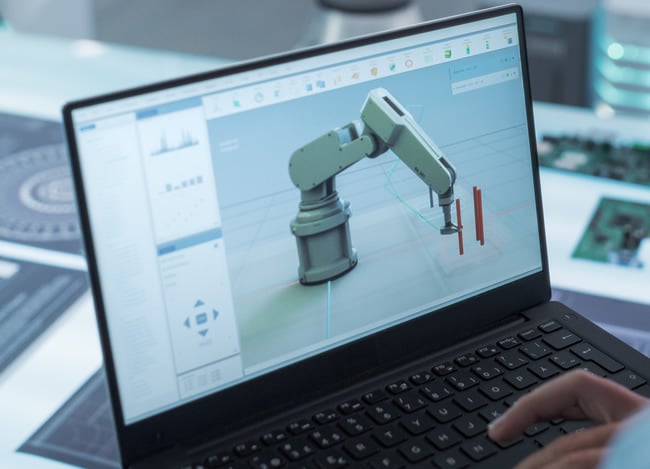

Robotic simulation

We utilise advanced robotic simulation software for precise and efficient simulations.

Robotic simulation software is a powerful tool that enables us to deliver precise 3D models and simulations of robotic systems to your business. This technology allows you to gain a comprehensive understanding of the system’s functionality before making a final design or layout commitment. Moreover, it provides invaluable insights into the system’s performance, confirming that desired cycle times can be achieved. By conducting simulations, we not only save you time and money but also proactively identify potential issues that might have gone unnoticed until after installation, ensuring a smoother and more cost-effective implementation process.