A turnkey system refers to a fully operational setup that is delivered to the user in a ready-to-use state.

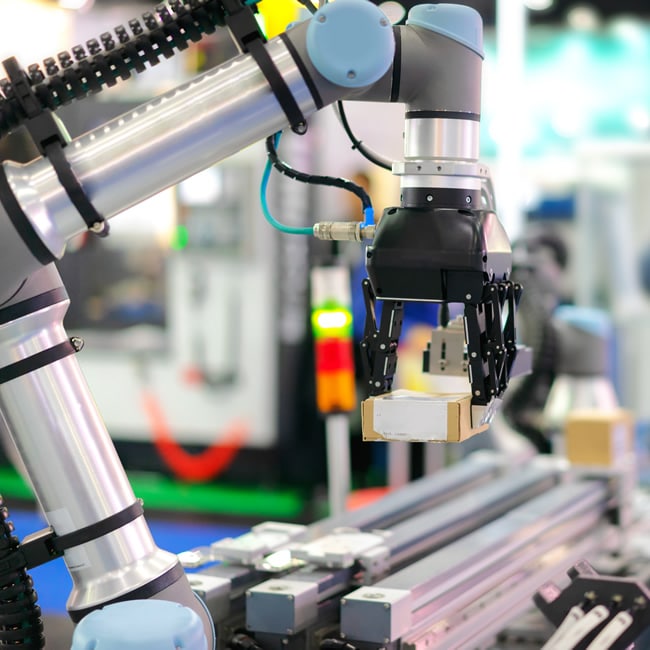

In the context of machinery and robot cells, this means a complete package that includes not only the machinery and robots themselves but also the necessary software, control systems, and often the entire infrastructure required for implementation.

Key selling points are:

- Cost Efficiency

- Streamlined Integration

- Reduced Implementation Risks

ScalabilityTurnkey solutions for production lines

Turnkey solutions significantly streamline the integration of advanced machinery and robotic technology into manufacturing facilities. They are designed to meet specific industry needs, ensuring optimal performance and productivity. The comprehensive nature of turnkey machinery and robot cells reduces the burden on businesses, as they can rely on a single provider for the entire system, from design to installation.

Key selling points are:

- Faster Deployment

- Comprehensive Support

- Consistent Quality